Solid Carbide Rods

![]() Introduction of Solid Carbide Rods

Introduction of Solid Carbide Rods

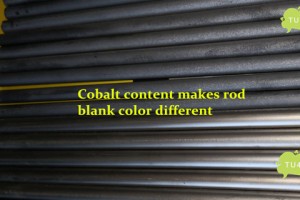

Solid carbide rod is mainly made of tungsten carbide, binder metal cobalt and some other functional ingredients added as formula requires, through materials mixture, extruding, pre-sinter, shape modification producing process then sintered in low pressure. With characters of high hardness, high strength, chemical stable, low expansion coefficient, electric and heat conducting, the sintered tungsten carbide rods are widely applied in industrial manufacture area, for example, to make micro drill in PCB industry, electrode bar in optical community industry, drill, drill stock, tip, pusher, wear resistant precision parts, CNC reamer and blades with coolant hole in machining industry.

As a carbide depot, Toonney tungsten metal plant factory manufactures a large range of tungsten alloy including solid rods, rods with straight/spiral coolant hole, shaped rods according customer’s requirement and T shaped etc.

Solid tungsten carbide rods, no coolant ducts inside. We have 10 grades formula material for most common use, for example, rods for PCB micro drill, micro milling cutter, carbide saw blade, drills to machining aluminum alloy, copper base alloy, steel base alloy and; wolfram carbide etc. We strictly control the quality in each necessary step, we can say good quality is one of advantages which makes us stand in this industry.

Wolfram carbide:Wolfram carbide is a compound composed of wolfram and carbide. It is a black hexagonal crystal with metallic luster, of which hardness is similar to diamond.Wolfram carbide is good conductor of electric and heat, can not dissolves in water,hydrochloric acid or sulfuric acid,but easily to dissolve in mixed solution of nitric acid and hydrofluoric acid. Pure wolfram carbide is fragile, but adding titanium or cobalt and sintered,the roughness will be much higher. Wolfram carbide is also called tungsten carbide.

Tungsten metal/Tungsten metallic: Tungsten is also called wolfram, the most form of tungsten metal in industrial application is tungsten carbide. Toonney tungsten metal factory has produced solid carbide rods for many years and gets good reputation at home and abroad.

Packaging Details: Plastic bag, then protected in foam lay, finally to an outer carton.

Samples Matters: Solid carbide rods which can be available from our common regular inventory, can be offered as samples for free. For solid carbide rods with irregular customer special required, will be charged. Of course, customers need to pay for the shipping fee. Usually, the lead time of the samples will be within 7working days.

Minimum Order Quantity: There is no minimum order quantity of solid carbide rods for the first trial order. But on the second order, the total amount of solid carbide rods should be not less than 1000 USD.

Delivery Time: 7-15 working days

![]() Cutting Tools Grade Table and Application

Cutting Tools Grade Table and Application

| Grade | Co % | Grain Siz(μm) | Density(g/cm3) | Hardness(HRA) | TRS(N/mm2) |

| TU90 | 9.0 | 0.2 | 14.35 | 94.1 | 5200 |

| TF06 | 6.0 | 0.6 | 14.81 | 93.1 | 4000 |

| TU06 | 6.0 | 0.4 | 14.8 | 94.3 | 4600 |

| TU08 | 8.0 | 0.4 | 14.52 | 93.5 | 4800 |

| TU08S | 8.0 | 0.3 | 14.5 | 93.6 | 5000 |

| TU40 | 10.0 | 0.8 | 14.4 | 91.7 | 4600 |

| TU40F | 10.0 | 0.6 | 14.45 | 92.3 | 4600 |

| TU40S | 10.0 | 0.5 | 14.5 | 92.5 | 4800 |

| TU44 | 12.0 | 0.4 | 14.1 | 92.6 | 4800 |

| TU25 | 12.0 | 0.6 | 14.06 | 92.5 | 4200 |

| TU45 | 13.0 | 0.3 | 13.95 | 92.7 | 4800 |

| TU55 | 13.0 | 0.3 | 13.92 | 92.6 | 4800 |

![]() Recommanded Application

Recommanded Application

| Grade | Recommanded application |

| TU90 | For cutting tools machining quesnched material(HRC65-70),hardwood and high polishing cutters. Excellent for cutters finish machining 316L stinless steel |

| TF06 | For cutting tools machining aluminum magnesium alloy,graphite and composite fiber. |

| TU06 | For PCB micro-drill and end mill machining super high harness metals. |

| TU08 | For PCB micro-drill,mini milling cutter. |

| TU08S | For micro PCB drill, cutting tools for finis machining quenched materials(HRC60-65),316L stainless steel, high polishing metal sheet and silicon steel sheet of motor. |

| TU40 | For common drill bit, end mill and punching die. |

| TU40F | For common drill bit, end mill machining titanium alloy, stainless steel and gray cast iron. |

| TU40S | For cutting tools machining 316L stainless steel, best material for common circular cuctters. |

| TU44 | For cutting tools machining titanium alloy, heat resistant alloy, stainless steel, quesnched steel(HRC55 and above),gray cast iron. |

| TU25 | For cutting tools machining heat treated steel(Hardness HRC45 and above),cast iron, stainless steel. |

| TU45 | For cutting tools machining titanium, heat resistant alloy, stainless steel, quesnched steel(HRC60 and above) |

| TU55 | Grade with high red-hardness, good for cutting tools machining high temperature resistant alloy, quenched steel(HRC60 and above) and titanium alloy |

![]() Specification of Solid Carbide Rods

Specification of Solid Carbide Rods

| Dia. Ø

mm |

Tolerance.(mm) | Length(mm) | Tol.(mm) | Dia.Ø(mm) | Tolerance.(mm) | Length(mm) | Tol.(mm) |

| 2.0 | +0.30/+0.15 | 330 | 1.5 | 16.5 | +0.8/+0.3 | 330 | 1.5 |

| 2.5 | +0.30/+0.15 | 330 | 1.5 | 17.0 | +0.8/+0.3 | 330 | 1.5 |

| 3.0 | +0.50/+0.30 | 330 | 1.5 | 17.5 | +0.8/+0.3 | 330 | 1.5 |

| 3.5 | +0.50/+0.30 | 330 | 1.5 | 18.0 | +0.8/+0.3 | 330 | 1.5 |

| 4.0 | +0.50/+0.30 | 330 | 1.5 | 18.5 | +0.8/+0.3 | 330 | 1.5 |

| 4.5 | +0.50/+0.30 | 330 | 1.5 | 19.0 | +0.8/+0.3 | 330 | 1.5 |

| 5.0 | +0.50/+0.30 | 330 | 1.5 | 19.5 | +0.8/+0.3 | 330 | 1.5 |

| 5.5 | +0.50/+0.30 | 330 | 1.5 | 20.0 | +0.8/+0.3 | 330 | 1.5 |

| 6.0 | +0.50/+0.30 | 330 | 1.5 | 20.5 | +0.8/+0.3 | 330 | 1.5 |

| 6.5 | +0.50/+0.30 | 330 | 1.5 | 21.0 | +0.8/+0.3 | 330 | 1.5 |

| 7.0 | +0.50/+0.30 | 330 | 1.5 | 21.5 | +0.8/+0.3 | 330 | 1.5 |

| 7.5 | +0.50/+0.30 | 330 | 1.5 | 22.0 | +0.8/+0.3 | 330 | 1.5 |

| 8.0 | +0.50/+0.30 | 330 | 1.5 | 22.5 | +0.8/+0.3 | 330 | 1.5 |

| 8.5 | +0.50/+0.30 | 330 | 1.5 | 23.0 | +0.8/+0.3 | 330 | 1.5 |

| 9.0 | +0.60/+0.30 | 330 | 1.5 | 23.5 | +0.8/+0.3 | 330 | 1.5 |

| 9.5 | +0.60/+0.30 | 330 | 1.5 | 24.0 | +0.8/+0.3 | 330 | 1.5 |

| 10.0 | +0.60/+0.30 | 330 | 1.5 | 24.5 | +0.8/+0.3 | 330 | 1.5 |

| 10.5 | +0.60/+0.30 | 330 | 1.5 | 25.0 | +0.8/+0.3 | 330 | 1.5 |

| 11.0 | +0.60/+0.30 | 330 | 1.5 | 25.5 | +0.8/+0.3 | 330 | 1.5 |

| 11.5 | +0.60/+0.30 | 330 | 1.5 | 26.0 | +0.8/+0.3 | 330 | 1.5 |

| 12.0 | +0.60/+0.30 | 330 | 1.5 | 26.5 | +0.8/+0.3 | 330 | 1.5 |

| 12.5 | +0.60/+0.30 | 330 | 1.5 | 27.0 | +0.8/+0.3 | 330 | 1.5 |

| 13.0 | +0.60/+0.30 | 330 | 1.5 | 27.5 | +0.8/+0.3 | 330 | 1.5 |

| 13.5 | +0.60/+0.30 | 330 | 1.5 | 28.0 | +0.8/+0.3 | 330 | 1.5 |

| 14.0 | +0.70/+0.30 | 330 | 1.5 | 28.5 | +0.8/+0.3 | 330 | 1.5 |

| 14.5 | +0.70/+0.30 | 330 | 1.5 | 29.0 | +0.8/+0.3 | 330 | 1.5 |