Heading Die

![]() Introduction of Heading Die

Introduction of Heading Die

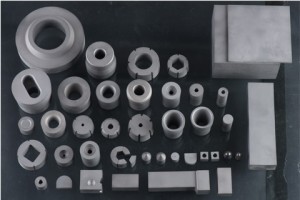

The application in cold heading die area is one of the main applications of tungsten carbide material. Heading dies usually can be divided into punching die and bushing die, used in cold heading, warm heading, and hot heading technology situation. Toonney corrosion resistant metal plant applies high-quality corrosion resistant metal with good wear resistance. Toonney corrosion resistant metal plant is famous for its cold heading die and stamping die with a factory-price. Why can Toonney corrosion resistant metal plant offer a lower price for customers? Because Toonney corrosion resistant metal plant gets many supporting from previous customers and local government. Welcome to Toonney corrosion resistant metal plant for more information about stamping die and cold heading die.

Cold heading is a process technology which makes the workpiece transformation and the shape close to the finished product to the utmost extent in few processes. It is the footstone of modern machining and automobile industry. Toonney cold heading dies factory manufactures various heading die including drawing die, cold heading dies, precision dies, carbide dies, stamping die and forging die. Thanks to the government supporting police, Toonney cold heading die factory can offer really cheap cold heading die and stamping die.

Toonney stamping die manufacturer has gotten more and more popular at home and abroad. Because Toonney stamping die manufacturer has rich experience of producing stamping die. The design team of Toonney stamping die manufacturer is a really professional team with international level. As a famous local stamping die manufacturer, Toonney stamping die manufacturer gets some supporting from the government. So Toonney stamping die manufacturer can offer a good price also.

Under strong impact wear working conditions, tungsten carbide cold heading dies are required hard alloy has good impact toughness, fracture toughness, Fatigue strength, flexural strength, and good wear resistance.

1. Usually used in high cobalt and the coarse-grained alloy grades.

2. Carbide wear resistance, toughness relationship between the two are contradictory: to improve the wear resistance will lead to a decrease in toughness, and improve toughness and wear resistance inevitably lead reduction. Therefore, the choice of alloy grades, the need to work in accordance with the object and process conditions to meet specific requirements.

3. If the selected grades in use, prone to crack and damage early, should use a higher toughness grade; if the selected grade in use early wear and damage, should use high hardness, wear resistance and better grades. Toonney has below grades for stamping die options.

| Grade | Density | Hardness | TRS | Impact force resistance |

| (g/cm³) | (HRA) | MPA | J/CM2 | |

| EVA80 | 13.58 | 84 | 2740 | 0.85 |

| RVA90 | 13.39 | 82.5 | 2350 | 0.9 |

| RVA95 | 13.1 | 81.5 | 2150 | 0.96 |

| XK5 | 31.1 | 83 | 2250 | 0.95 |

| RST7 | 13.4 | 85 | 2640 | 0.8 |

| RST8 | 13.3 | 84 | 2640 | 0.9 |

Samples Matters: Cold heading die and stamping die which can be available from our common regular inventory, can be offered as samples for free. For some cold heading die and stamping die with irregular customer special required, will be charged. Of course, customers need to pay the shipping fee. Usually, the lead time of the samples will be within 7 working days

Minimum Order Quantity: There is no minimum order quantity of cold heading die and stamping die for the first trial order. But on the second order, the total amount of cold heading die or stamping die should be not less than 1000 USD.

![]() Specification of Heading Die

Specification of Heading Die

| Grade | Density | Hardness | Hardness | TRS | Compression strength | KIC |

| (g/cm³) | (HRA) | (HV) | MPA | GPA | MPA.m1/2 | |

| GA10 | 14.40 | 92.0 | 1865 | 3600 | 5.9 | 14 |

| RKG2 | 14.93 | 90.2 | 1586 | 3200 | 4.1 | 17 |

| RKG3 | 14.61 | 89.3 | 1447 | 3300 | 4 | 18 |

| RKG4 | 14.31 | 89.2 | 1431 | 3400 | 3.9 | 19 |

| RKG5 | 14.31 | 88.2 | 1276 | 3400 | 3.8 | 20 |

| RKG6 | 14.12 | 87.2 | 1177 | 3200 | 3.7 | 22 |

| RVA70 | 14.05 | 86.5 | 1076 | 3200 | 3.6 | 23 |

| RVA65 | 13.73 | 85.0 | 900 | 3000 | 3.4 | 24 |

| RVA80 | 13.58 | 84.0 | 832 | 2740 | 3.3 | 25 |

| RVA90 | 13.39 | 82.5 | 756 | 2350 | 3 | 27 |

| RVA95 | 13.10 | 81.5 | 709 | 2100 | 2.8 | 28 |

| RST6 | 13.70 | 85.8 | 972 | 2740 | 3.5 | 23 |

| RST7 | 13.40 | 84.8 | 886 | 2640 | 3.3 | 24 |

| RST8 | 13.30 | 83.5 | 806 | 2640 | 3.1 | 27 |

| GW60 | 13.95 | 84.5 | 865 | 3270 | 3.8 | 18 |

| GW70 | 13.58 | 83.0 | 781 | 3050 | 3.6 | 22 |

| KC12 | 14.31 | 85.8 | 972 | 2740 | 3.7 | 18 |

| KC13 | 14.22 | 85.0 | 900 | 2740 | 3.6 | 20 |

| KC18 | 13.73 | 83.5 | 806 | 2740 | 3.3 | 22 |

| GA40 | 14.40 | 89.0 | 1400 | 3000 | 4.1 | 17 |

| GA50 | 14.20 | 88.5 | 1323 | 3100 | 4 | 19 |

| GA55 | 13.85 | 85.5 | 933 | 3000 | 3.7 | 21 |

| GA60 | 13.65 | 84.5 | 865 | 2900 | 3.6 | 24 |

Toonney cold heading die factory also can acceptcustomized tungsten products.

![]() The Feature of Heading Die

The Feature of Heading Die

Product name: Cold heading die/stamping die

Place of Origin: Fujian, China (Mainland)

Brand Name: Toonney

Model Number: CHD/SD

Type: Cold heading die/stamping die

Material: Tungsten carbide material

Tolerance: As required.

Grade: GA10,RKG2, RKG3, RKG4, RKG5, RKG6, RVA70, RVA65, RVA80, RVA90, RVA95, RST6, RST7, RST8, GW70, KC12, KC13, KC18, A40, GA50, GA55, GA60

Size: As required

Port: Xiamen

Payment terms: FOB Xiamen, TT

![]() Application of Heading Die

Application of Heading Die

GA10, RKG2, RKG3, RKG4 (Density and hardness as above table shows)

Fit for heading dies such as Bube drawing die, powder shaping die, nut and bolt die

RKG5, RKG6 (Density and hardness as above table shows)for scissor die, powder forming die, nut and bolt die.

RVA70 (With density 14.02, harness 85HRA) is specially applied for drawing the tight binding mold for screw and nuts

RVA65 (With density 13.73, hardness 85HRA) is for small dia. bolt dies, cold heading dies

RVA80 (With density 13.58, hardness 84HRA) is for big dia. bolt die, nut die, cold heading die

RVA90 (With density 13.39, hardness 82.5HRA) is for screw head shape mold, nut die, high-pressure stamping die

RVA95 (With density 13.10, hardness 81.5HRA) is for nut die, flower-shaped screw die, hot extruding die, super heavy stamping die

RST6 (With density 13.70, hardness 85.8HRA) applied to stainless steel screw die.

RST7 (With density 13.40, hardness 85HRA) applied to stainless steel screw die, impact resistant stamping die, screw die.

RST8 (With density 13.30, hardness 84HRA) applied to raised head screw die, impact resistant stamping die, double horn shape screw die, screw die, rivet die.

KC18(With density 13.73, hardness 83.5HRA) applied to screw stamping die

Please contact sales for any questions in selecting material grades.

![]() The Advantage of Heading Die

The Advantage of Heading Die

Toonney stamping dies factory controls the quality strictly, have inspection devices such as the HV, HRA tester, TRS tester, Carbon sulfur analyzer and high magnification metallurgical microscope to test the physical and chemical characteristics of tungsten carbide material. And the precise dimension device to control the shape tolerance.

Toonney stamping die manufacturer has more than 10 years production experience of stamping die and cold heading die.

Toonney imports advanced equipment and develop their own professional team for designing and producing cold heading die and stamping die.

Toonney cold heading dies factory can give the promise that all stamping die and cold heading die will have an inspection during producing and the final inspection after producing.

Toonney stamping dies manufacturer can accept the customized order of stamping die and cold heading die.